When shopping for flexible filaments, one of the major things you should look out for is shore hardness. You can find this information on the product’s page and on the flexible filament’s spool as well. But what exactly does shore hardness mean? And where does it apply?

Read on to find out.

What is a Durometer?

Before we get into the complicated stuff, it’s only right we start with identifying the tools we need. A Durometer is an instrument used to test the resistance of various materials, mainly rubber and plastics, to indentation with a particular degree of force. This tool is primarily used in manufacturing, shipping, shipping service industries, construction, weatherproofing, electrical and whatever else needs to be tested for resistance to indentation.

Many people have a rough idea of how hard a material is when they apply constant pressure in an attempt to indent it, but this is not an exact measurement. For this reason, the durometer and the shore scale were created so that people could discuss these elements from a common point of reference.

What is the Durometer Shore Hardness Scale

The Durometer Shore hardness scale is a relative scale of 0-100, in which 0 is the softest and natural-looking, and 100 is the hardest material. The higher the Shore Hardness, the harder it is to chip or cut with an object. Filaments with low Shore Hardness are usually soft, flexible, and easily broken down by tools. On the other hand, more hard materials are stronger and more resistant.

There are 3 main shore hardness scales used to test the hardness of different products. They include:

- The Shore 00 Hardness Scale used to measure rubber and soft gels.

- The Shore A Hardness Scale used to test flexible rubber that ranges between very soft and flexible and hard with no flexibility. The high end of this scale is also used to measure semi-rigid plastics.

- The Shore D Hardness Scale used to measure the hardness of hard plastics and semi-rigid rubber.

There are about 15 different Shore Hardness scales, but these 3 are the most used to measure the hardness of plastics, rubber, or any other non-metallic object.

How to Use a Durometer

What’s interesting is that the durometer is not a complicated tool to use. When measuring the hardness of the material, follows these steps:

- Choose the appropriate Shore hardness scale to use based on what you are testing.

- Place the sample you are testing on an even and hard surface that is at least 1/4-inch in thickness.

- Hold the durometer firmly in both hands and place it on the sample. Make sure the indenter is touching the sample.

- Record the reading on different parts of the sample and find the average for accurate results. And you’re done.

Do You Need the Durometer Shore Hardness Scale With Flexible Filaments?

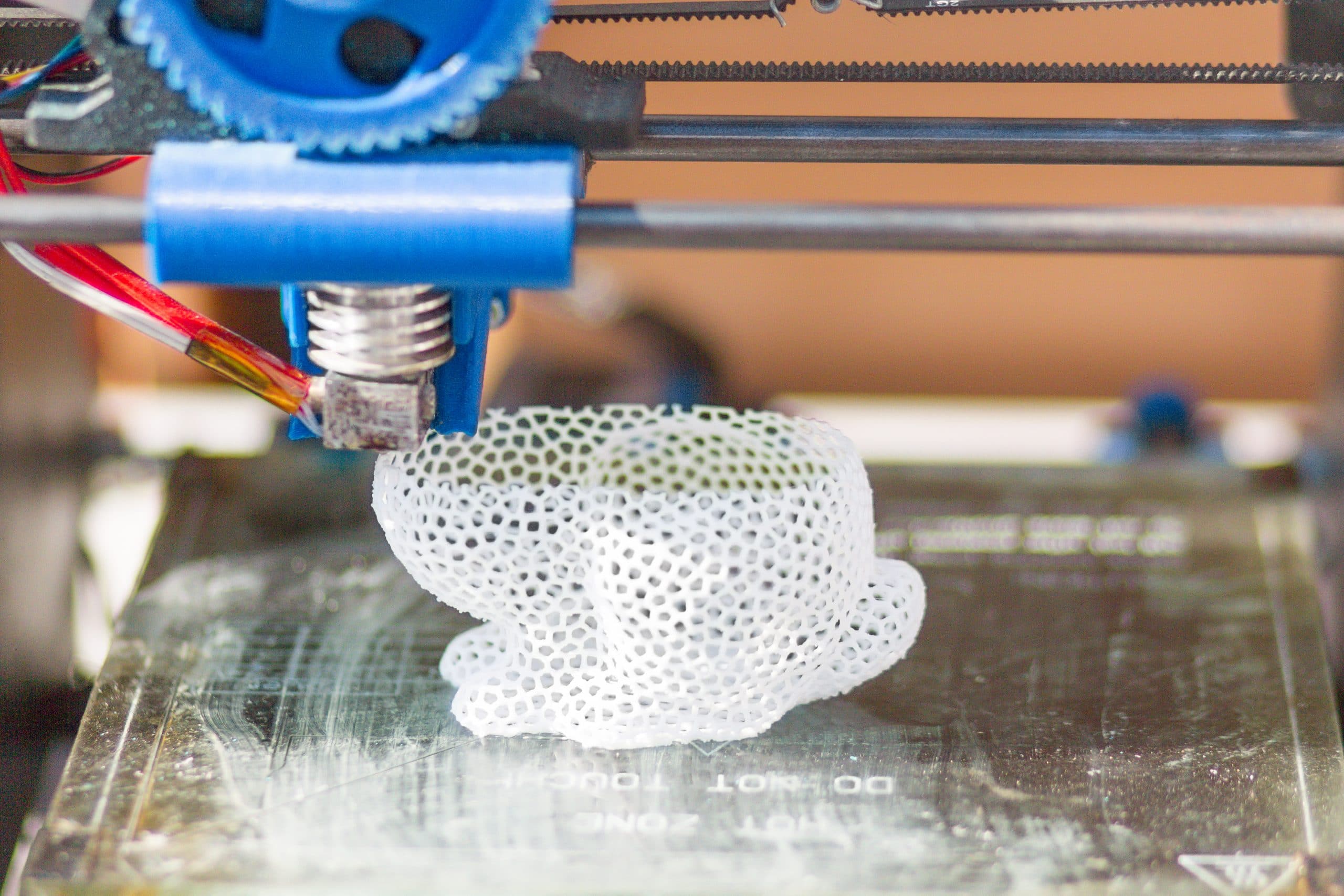

When it comes to flexible filaments, shore values can give you an idea of how easy it will be to print with a material. It’s important to know that the shore hardness tells you how easy or difficult it will be to manipulate your print. Somewhere between Shore A and Shore D is the right hardness for your application, but you need to know where on that scale you should shoot for.

Understanding the right hardness scale for your flexible filaments can make a big difference in how successful your projects are. Luckily, with this type of filaments, you don’t need a durometer. The shore hardness readings are right there on the box.

You Can Trust the Manufacturer's Shore Hardness Readings

There are three main parts to the testing process of flexible printing materials. The first is analysis, where technicians look at the strength, stiffness, and fatigue of materials to see if they are up to standard.

Then there is a qualification, where technicians use the materials to actually make things. Finally, there is evaluation, where people buy the finished goods and make sure they work as intended before handing them off for testing. The last step in any Material Testing process is certification.

When making your next purchase, make sure the flexible filament you choose has the right certification and make your TPE, TPU or TPC 3D printing a success.