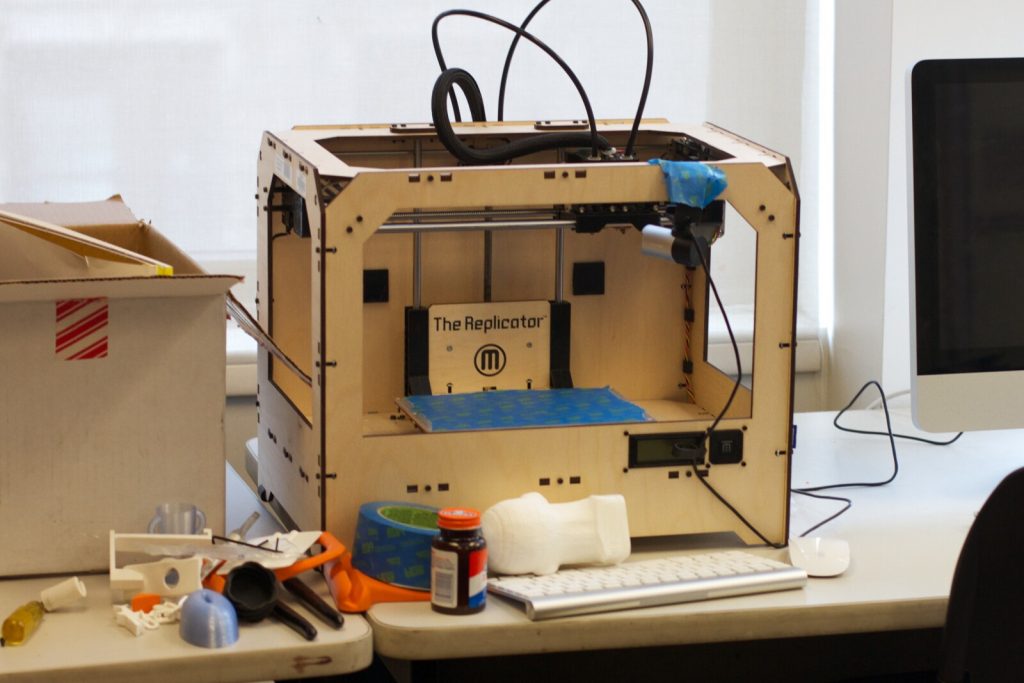

3D printers are sophisticated devices that give form and breathe life into your ideas. However, like any other piece of advanced technology, they come with their own share of problems. For one, it’s not uncommon for 3D printers to breakdown halfway through a printing job. When that happens, it can derail your new work of genius.

When stakes are this high, you cannot risk your 3D printer letting you down! Thankfully, you can prevent such mishaps from plaguing your 3D printing projects with a simple solution – regular maintenance.

Why Do 3D Printers Require Maintenance?

Every 3D printer out there requires some degree of maintenance. Some of them require more care than orders because of poor-quality components, but that’s not the only reason why 3D printers require regular maintenance. Here’s a quick guide on how and when to maintain a 3D printer:

- 3D printers feature plenty of reciprocating parts which suffer from wear and tear. Therefore, some of these parts may have to be repaired or replaced from time to time. Parts like nozzles wear out due to abrasive filaments and need replacement.

- The reciprocating parts, such as rails and rods, need good lubrication to move smoothly. As the lubrication dries up every few weeks, a regular checkup is necessary.

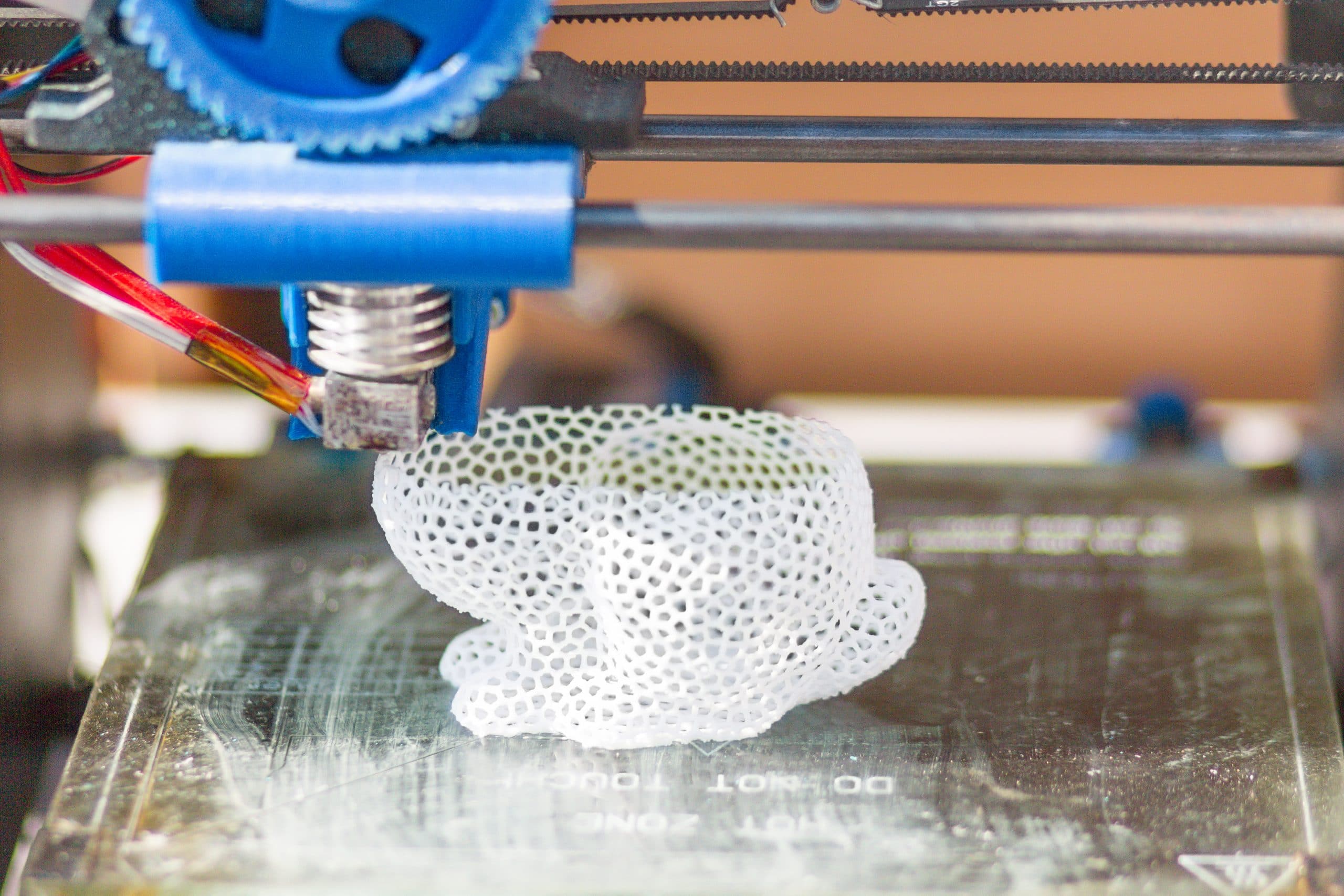

- Filaments are designed to melt and take the required shape. This makes them prone to sticking. They stick to nozzles, or other parts, and cause clogs in the 3D printing jobs, ultimately affecting their design, dimensions, and even structural integrity.

- The extruder, bearings, and gears often catch some gunk which affects their performance.

- The tape that covers the build surface area gets scratched and needs replacement.

How to Maintain 3D Printers

1. Lubricate movable parts with 1-2 drops of oil. It can be sewing oil or something more specific, as instructed by your 3D printer’s manufacturer in the manual.

2. All parts that witness some form of movement require monthly checkups. They may not need replacement every month, but a monthly checkup is critical. One way to identify nozzle issues is by measuring the width of the filament extrusion coming out of it.

3. The feeding gears, bearings, and extruder must be cleaned out manually to remove filament and gunk out of them. A good brush should help take care of most of the gunk. But, it’s also recommended to use a cleaning filament (which is sticky) to “catch” all the gunk as it passes through all contact surfaces.

4. It’s easy to recognize when the painter’s tape on the build surface needs replacement – it’s either ripped, broken or does not allow prints to stick to it. When that happens, rip off the tape and lay new tape in its place. If it doesn’t come off easily, you can use an adhesive remover.

How Much Does It Cost To Own And Maintain A 3D Printer?

Entry-level 3D printers cost around $200, while the top-of-the-line industrial 3D printers can cost as much as $100,000. In general, the monthly costs of operation and maintenance come up to 20% of the 3D printer’s cost.

The design and construction of 3D printers play a critical role when it’s time to maintain 3D printer. Prusa 3D printers, for instance, are designed to make your life easy. If you don’t want the hassle of complex maintenance tasks with your 3D printer, Prusa is the way to go.

Rule of thumb dictates – A 3D printer with a more complicated design demands higher maintenance.

Very nice write-up. I definitely appreciate this site. Thanks!