Simple and Easy Beginner’s Guide to Selecting Your First 3D Printer

A 3D printer opens up a whole new world for you. You can print anything you want – figurines, toys, phone cases, engineering designs – the potential is limitless.

If you are getting started with a 3D printer, choosing the right 3D printer can save you a great deal of frustration, delays, and setbacks. That’s why we’ve created this guide to offer you a quick and easy guide to help you get started with 3D printers.

First Things First, Why Do You Need a 3D Printer?

Seriously, do you really need a 3D printer? If yes, what for?

Your answer to these questions will determine the type of 3D printer you should get. If you are a hobbyist who’s looking to scratch the curiosity itch, then an entry-level 3D printer will do the job for you.

On the other hand, if you are an architect, you will need a high-performance 3D printer that creates flawless models and doesn’t slow you down.

What Kind of 3D Printer Should You Buy?

There are mainly three types of 3D printers available in the market, and they differ vastly in their technology, applications, and costs. Here’s a quick lowdown on them:

Filament Deposition Method (FDM) / Fused Filament Fabrication (FFF)

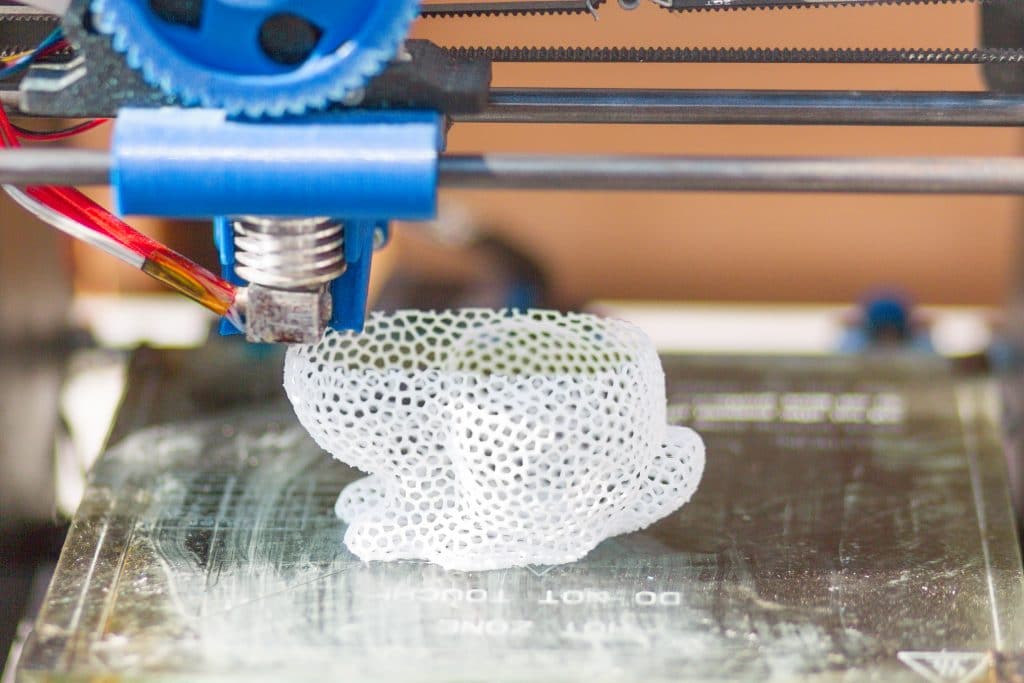

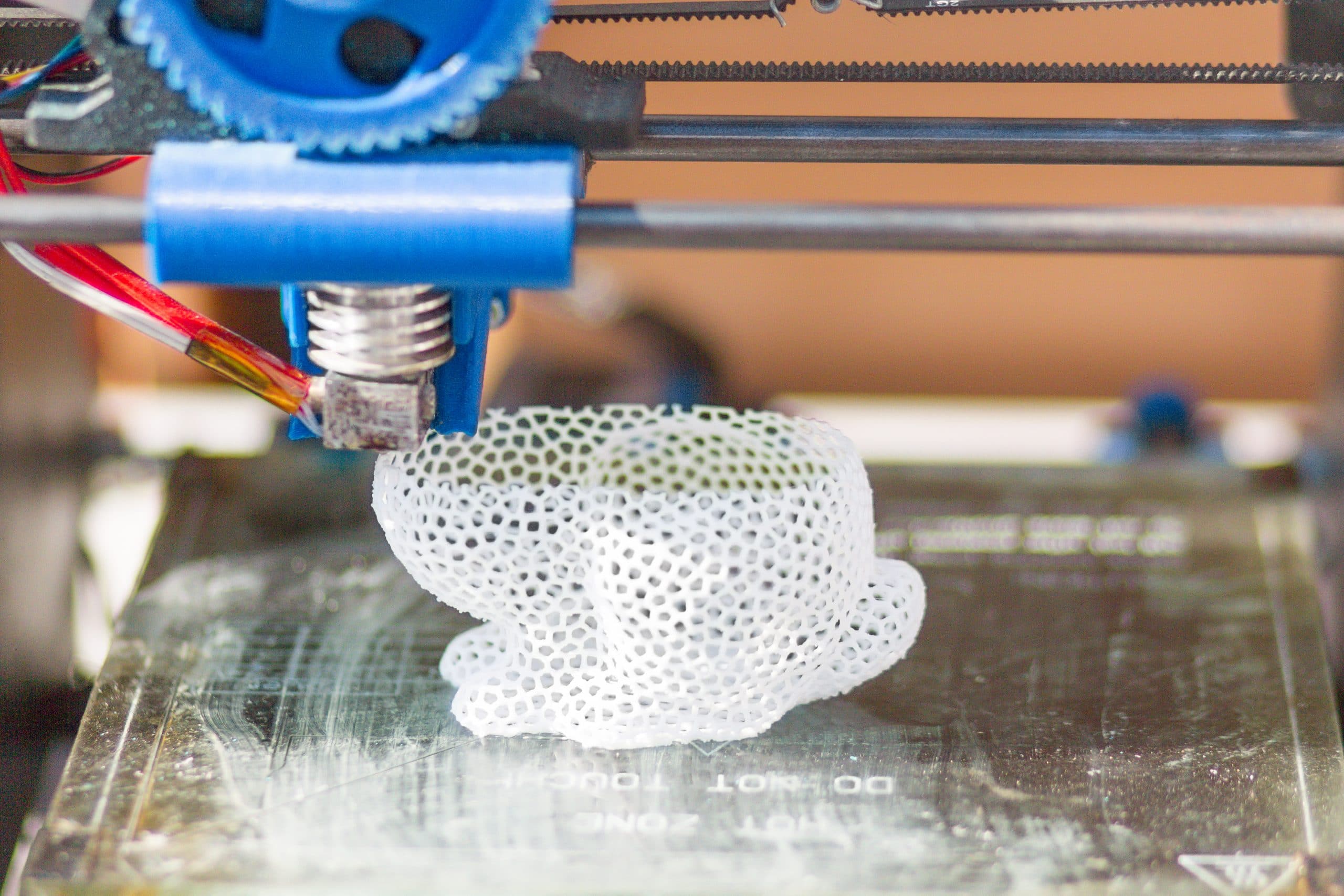

FDM (or FFF) 3D printers push a plastic filament through a heated nozzle, while the nozzle moves along three geometrical axes – X, Y, and Z – to deposit the extruded material in a predetermined design or form.

Here are some of the features of FDM 3D printers:

- They are the cheapest options available

- They are not the most accurate 3D printers out there. They are not ideal for 3D printing layers of size 100 microns or smaller

- The 3D printed surfaces are coarse

Stereolithography (SLA) / Digital Light Processing (DLP)

SLA 3D printers make use of a liquid photopolymer resin, which solidifies when exposed to light. The printer uses a laser to target specific areas of the resin and cure (solidify) it. DLP lasers, too, use a similar resin that solidifies when exposed to ultraviolet light.

Here are some features of SLA and DLP 3D printers:

- These 3D printers are highly accurate, with 3D printing resolutions as impressive as 25 microns.

- They offer a smooth finish

- SLA and DLP printers come at entry-level and mid-level prices

Selective Laser Sintering (SLS)

SLS 3D printers make use of powdered material, which is hardened with a laser. The powdered material is placed in layers, and it is hardened in specific areas using the laser. Then, another layer of the material is applied. Typically, 3D printed models using the SLS method need to be baked subsequently to eliminate the binding material and retain only the core material.

Here are some features of SLS 3D printers:

- SLS printers are used for industrial applications

- They are the most expensive 3D printers around

- They support a remarkable variety of materials

- The most accurate 3D printers

Conclusion

Now that you know the basic types of 3D printers out there, you must consider your own needs to select the right 3D printer for you. Factors like maintenance needs, prices, operational costs, post-processing of 3D printed models, and how much time you’d like to spend with your 3D printer go a long way in determining what’s the ideal 3D printer for you.